How Waterproof Coating Works for Dry Bags

Table of Contents

1. Introduction

2. Types of waterproof coatings for dry sacks

3. Advantages of waterproof coating of dry sacks

- Resistant to water damage

- Resists abrasion and puncture

- Extends the life of the dry bag

4. Application process of waterproof coatings on dry ration packs

- Preparation

- Application

- Drying

5. Frequently asked questions

- How do I determine the effectiveness of a waterproof coating on a waterproof bag?

- Will the waterproof coating on a dry bag degrade over time?

- Does the coating make the bag completely waterproof?

6. Conclusion

Introduction

Outdoor activities are both exciting and can bring unforeseen risks, particularly the threat of water damage to participants' belongings. For adventure sports companies, business owners and outdoor activity organisers, providing high-quality waterproof bags not only helps to enhance brand image but also customer loyalty.

However, as a business owner, it can often be a challenge to find a reliable supplier to ensure that you provide your customers with waterproof dry bags that they can trust.

In this article, we will explore the different types of waterproofing coatings and their benefits, as well as describe the process of applying them. Armed with this knowledge, you'll have a clearer picture of the options available to you so that you can find a trustworthy supplier to produce your waterproof dry bags.

Different Types of Waterproof Coating for Dry Bags

When it comes to waterproof coatings for dry bags, there are two main types used in the industry today - Polyvinyl chloride (PVC) and Thermoplastic Polyurethane (TPU).

PVC is a synthetic plastic polymer that is widely used in various industries due to its low cost and durability. PVC coating has been used in dry bags for many years and is still widely popular today. It provides excellent waterproofing properties and is suitable for general-purpose applications.

TPU, on the other hand, is a thermoplastic polymer known for its strength, flexibility, and resistance to abrasions and oils. TPU coating is typically more expensive than PVC but offers superior strength and durability. It is also environmentally-friendly and free from harmful phthalates, making it a popular choice for eco-conscious customers.

Advantages of Waterproof Coating for Dry Bags

Protection from water damage

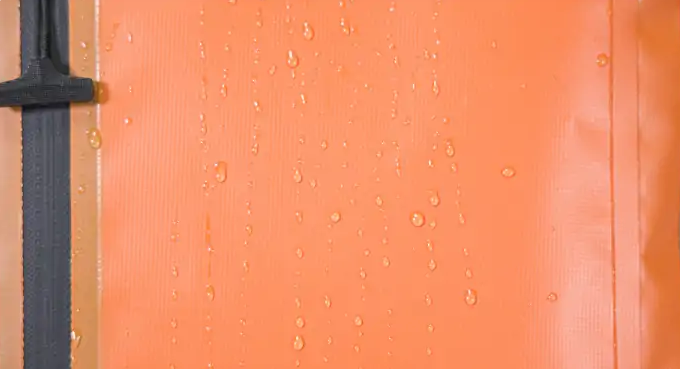

Protection from water damage is the key function of dry bags. Most dry bags use waterproof resistant fabrics, which is not enough to protect its belongings without waterproof coating. Waterproof coating creates a barrier against water that, when water comes in contact with a waterproof bag, the coating prevents the water from seeping through the fabric and damaging the contents inside.

Resistance to abrasions and punctures

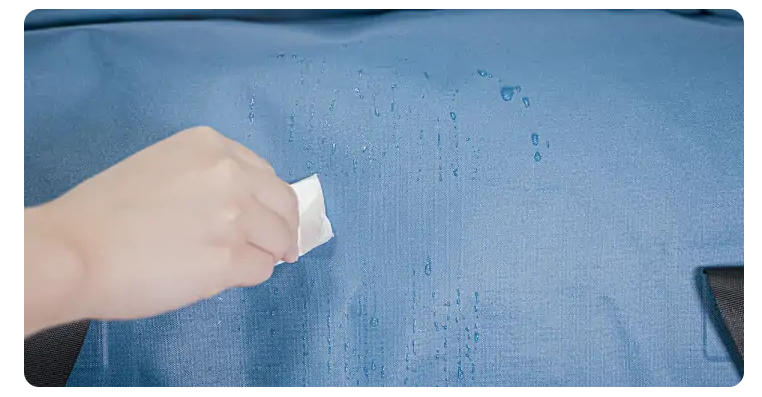

Aside from protection from water damage, waterproof coating also enhances the durability of the dry bag by providing resistance to abrasions and punctures. The coating forms a protective layer against any external pressure to prevent the fabric from wear and tear, ensuring that the bag is more durable and can withstand extreme outdoor conditions.

Extended lifespan of dry bags

Dry bags with waterproof coatings have a longer lifespan than those without coatings. When protecting the dry bag from water, waterproof coating also prevents bacteria and other microorganisms from seeping into the fabric. This, combined with the protection from wear and tear, extends the lifespan of dry bags and saves the cost of maintenance for your customers.

The Process of Applying Waterproof Coating to Dry Bags

In most cases, waterproof coating is applied to the fabric material before it is made into a dry bag. Generally, the process is divided into three steps: preparation, application, and drying.

Preparation

Before applying the waterproof coating, the fabric material undergoes thorough cleaning to remove any debris that may interfere with the coating process. The fabric must be completely dry before the coating application begins. Otherwise, impurities can compromise the strength and durability of the final product.

Application

Once the base fabric is prepared, the coating material is applied to one or both sides of the base. This is done using a coating machine where the fabric is guided through the machine while the coating material is spread onto it. Depending on the intended use, coating can be applied in different thicknesses.

Drying

After coating is applied to the base fabric, the material is then dried by passing it through a high-temperature oven to evaporate any solvents used during the coating process. This ensures that the coating adheres well to the base fabric, and also helps to set the final shape of the material.

Frequently Asked Questions

How do I know if a waterproof coating on a dry bag is effective?

One way to test the effectiveness of waterproof coating on a dry bag is to fill the bag with water and leave it overnight. If the bag remains dry inside, then the waterproof coating is effective. You can also check for any signs of wear and tear or damage on the bag, which may indicate that the waterproof coating has been compromised.

Will waterproof coating on a dry bag wear off over time?

Yes. The waterproof coating on a dry bag can wear off over time due to exposure to external factors such as UV light, heat, and abrasive surfaces. When storing and selling dry bags, avoid prolonged exposure to such elements, and let consumers know they should follow this instruction too.

Can waterproof coating make a dry bag completely waterproof?

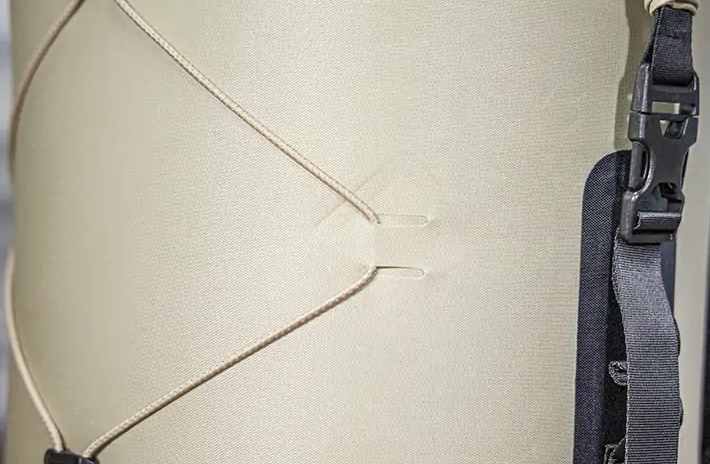

While waterproof coating adds a significant level of protection against water damage, other factors may affect the bag’s ability to repel water, including the quality of the bag’s seams and zippers, the bag’s design, and the level of water exposure.

Conclusion

In conclusion, waterproof coating for dry bags is a crucial component that protects your customer's belongings from water damage, abrasions and punctures, and extends the life span of the bags. As a business, choosing what type of waterproof coating for dry bags does not solely depend on your preference, but also on your customer’s specific needs and your budget requirements.

When selecting a supplier for waterproof dry bags, it is essential to find one whose quality meets or exceeds your standard so that you can offer your customers a reliable product that is built to perform and protect. This is best checked by testing samples before your bulk order. At HoneyDryBag, we provide our clients like you with high-quality dry bags made of selected materials with rigorous manufacturing process and quality control measures. We are dedicated to providing you the most sincere service and delivering customizable dry bags with your private logo printed to meet your business needs and help you grow your brand, Contact us today and learn more about how we can service your business and meet your requirements for waterproof dry bags.